Australia is rich in fresh produce but short on labour . This labour scarcity has been escalated due to the pandemic, resulting in less fruit and vegetables harvested.

For consumers, it means paying more for the same produce. For farmers, it means automation becomes an unavoidable choice. When you don’t have access to sufficient pickers and supervisors, you need to rely on tech.

But is that the only benefit of automation – less reliance on human labour?

No, it’s not. Digitising your fresh produce quality control does so much more!

Reducing food waste with automation

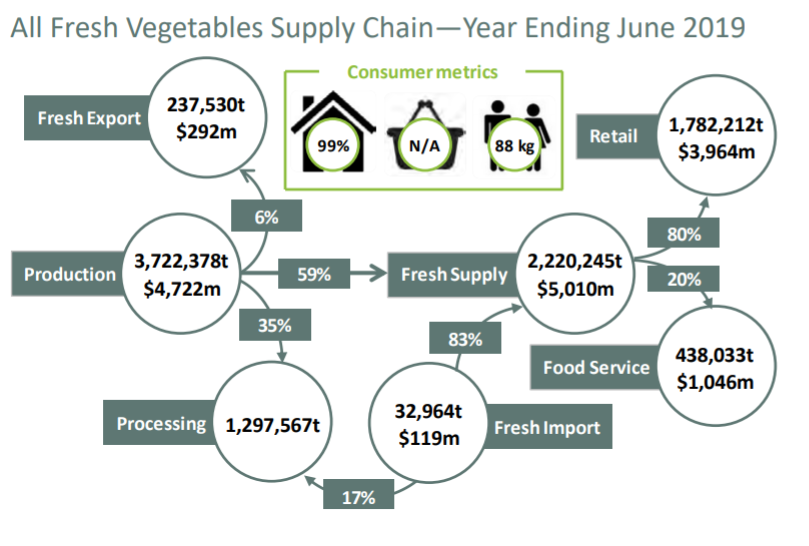

Before Australian fresh produce leaves the farm, 31% of it is wasted. Of the remaining that enters the cold chain, 25% is wasted, considerably more than the losses experienced in meat, seafood and dairy.

To highlight this a teen in Queensland recently created a dress out of mango seeds from wasted mangoes.

That’s just one farm. Can you imagine the sheer volume of fruit thrown away across the country?

Automating in-field assessment can minimise this food waste. How? Because digitising accurately sorts fresh produce and redirects produce that fails to match high quality consumer standards.

And reducing wastage is not the end of it. What automation really brings to the table is objectivity and efficiency in grading quality, saving time and labour, whilst improving accuracy.

Making quality control efficient

Let’s say you are a berry or grape grower. You will have a harvest crew that picks, sorts and packs your produce. Before it is sent to a cool room or packhouse, a trained supervisor assesses a sample of the quality one more time.

The process is slow and prone to human error because even the most expert pickers and supervisors have an unconscious bias. The accuracy is made worse by the time consuming nature of the process, reducing the number of inspections completed. And it requires investment in a high level of quality control training, not to mention the number of supervisors.

Quicker inspection

When you digitise quality control, you reduce time-to-market and improve productivity because a tool that automatically grades berries or grapes can sort more product in less time more accurately.

Stable assessment

People are predisposed to making mistakes with different people making different mistakes, leading to inconsistency in grading. So, irrespective of how tightly you run the ship, defective produce or those that don’t match quality standards always slips through.

When you digitise, quality assessment becomes objective. There is minimal human intervention; therefore, there are less errors. You simply set the quality parameters once, and the tool continuously and accurately assesses which produce meets them or not, improving its own accuracy with each inspection.

Solid accountability

When you use human eye for quality control and Excel to track the data, sharing the same with customers is unproductive as it is difficult to follow trends and interrogate the data.

Digitising records all the required quality attributes such as colour, size and defects. It makes your data traceable and the most accurate it can be, delivering accountability. The information can then be used as the basis for any quality issues that may manifest in transit.

The Gist?

Farmers and growers can reap many benefits by automating crucial tasks like physically and visually inspecting fresh produce. And all of them lead to one advantage – profitability.

Ready to start your digitisation journey and reap the rewards? Get the one app for all your quality inspection needs!

Brett Jackson is the Managing Director of Fresh Domain, with two decades of experience in the agricultural sector. Intello has partnered with him for go-to-market strategies in Australia. You can connect with him on LinkedIn