This #WorldFoodSafetyDay, we aim to raise awareness on how AI goes a long way in keeping food safe.

From 2004 to 2010, the United States had 1779 food borne outbreaks. Of these, 9.2% were attributed to fresh produce. From 2010 to 2017, it had 1797. Not a noteworthy increase. But those attributed to fresh produce jumped to a whopping 12.7%.

Fresh fruits and vegetables naturally don’t contain bacteria, viruses, and parasites. It is the soil, water, and animals that contaminate them rather easily.

But what poses a greater threat and the likely reason for more outbreaks are pre-and post-harvest practices. The way fresh produce is handled, stored, or transported has marked ramifications on safety.

AI long found its place in food safety

Improving traceability with cloud data storage, automatically measuring risk factors like temperature or using an artificial nose to detect rot. AI can be used in all sorts of ways to modernize and improve food safety.

But since careless and untrained workers are one of the biggest sources of contamination, we focus on how AI overcomes these limitations of the human workforce.

Accuracy of machine vision

The human eye often struggles to inspect produce. There is too much variability in what a tomato or grape should look like or the kind of contamination it can have.

Unless the person is trained extremely well, unsafe food eventually passes unchecked.

Now with machine vision, we get augmented sight. So much so, that it can catch parameters human senses would miss. It performs the same inspection but with far more accuracy. And it does so with speed, analyzing data streams in quantities a human would find overwhelming.

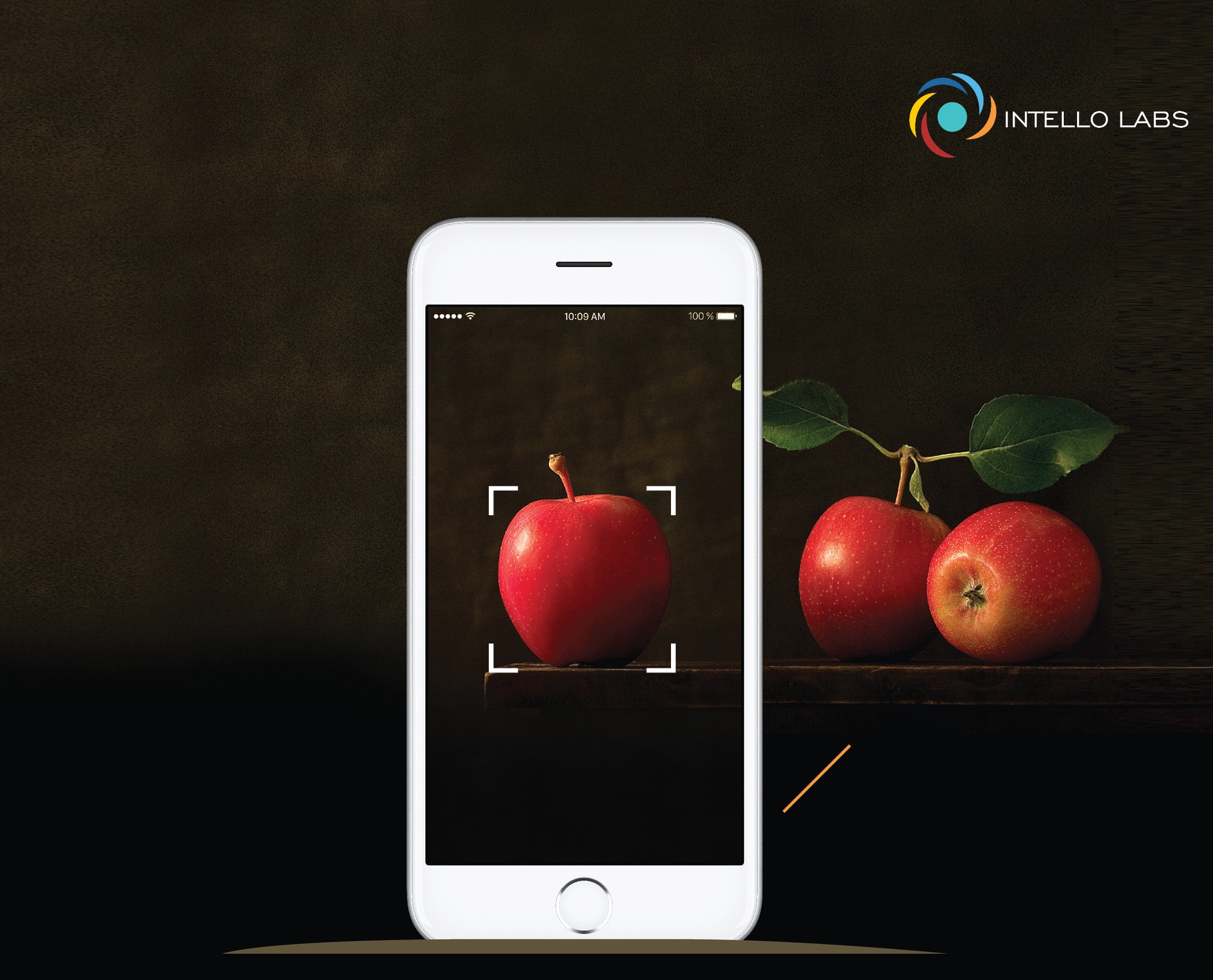

AI works 24/7, without fatigue

Another trouble with manual inspections is variation. For an average person, an apple that is defective today might seem acceptable the next.

The reasons vary - obstructed vision, bad lighting, interrupted inspections, lack of proper compliance documentation. However, most of the slipups happen due to cognitive fatigue in overworked inspectors.

AI-based solutions don’t tire, even when they work round the clock. It guarantees that contaminated food does not make it through. That such tools are as easy to use as an average mobile app and have an unerring ability to inspect in a wide variety of lighting are incidental benefits.

Sensors detect contamination

Sorting is hands down the most time-consuming process in food quality. It is also labor-intensive and inconsistent. Sensor-based sorting machines come with unprecedented contaminant detection capabilities.

They completely weed out foreign matter using 360 degree scanning, offering better, safer quality at higher yields. That they do so in fewer hours with less waste is just the cherry on top.

ML saves safe food

Conventionally, we sort fresh produce either as rejected or accepted. This ‘good or bad’ logic creates heaps of food waste. Machine learning can filter at least part of that produce to more useful purposes.

By applying a degree of intelligence, it can redirect fresh produce to more appropriate channels, like food processing. Thereby save a phenomenal amount of food loss – food that was safe to consume but would have been thrown away merely because it didn’t suit one particular purpose.

The takeaway

The UN and FAO emphasize that food safety is everyone’s business. We agree. From the grower to the retailer, every link in the food value chain can ensure it.

And it doesn’t take a lot to implement. For instance, something as simple as shifting to paperless technology and automating workflow contributes significantly.

So, this World Food Safety Day, let’s break the tyranny of unsafe food. Because unsafe food is the same as no food at all. Learn how Intello Labs’ suite of products help make food safer.